Requirement

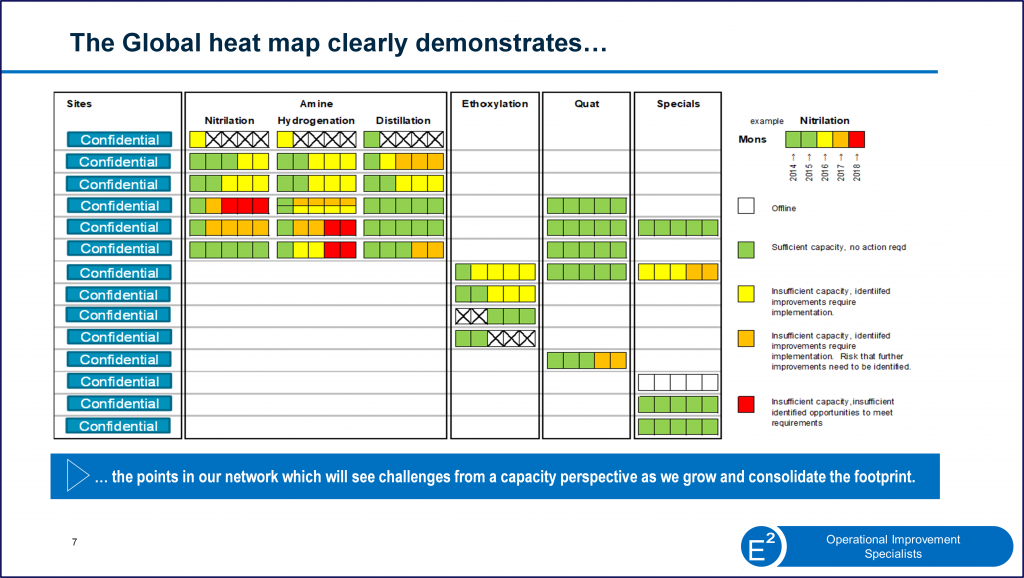

- Create the Global Asset Strategy linking directly to the BU Strategy with 5 year outlook.

- Create a process to allow updates of the Asset Strategy as the BU Strategy moves over time.

Challenge

- The business has historically operated regionally with most plants running in a highly autonomous way. Consistent data across the global footprint was totally missing and an understanding of asset capabilities was largely undocumented.

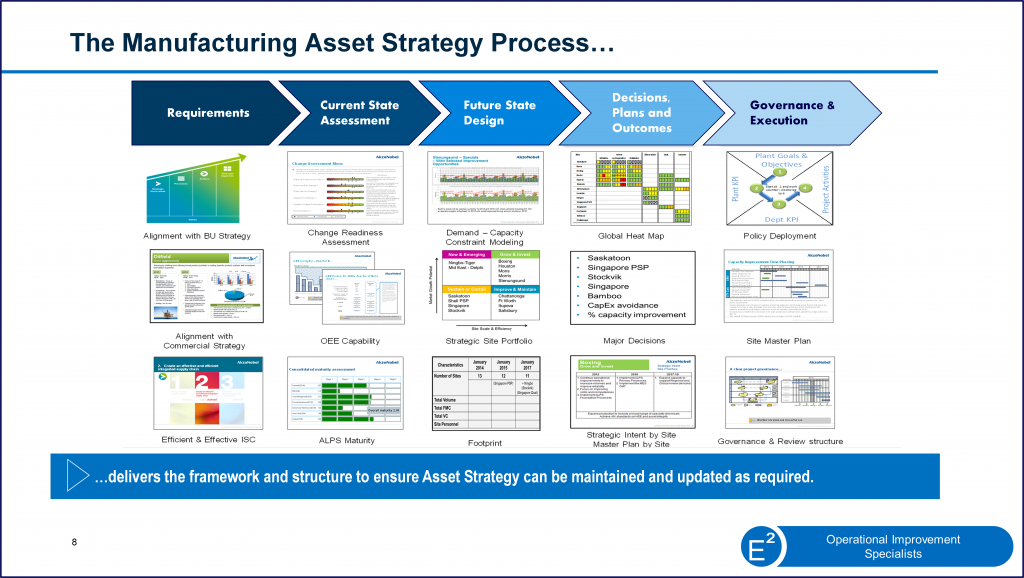

Approach

- Create a working model with 1st draft output from the model.

- Define Operational Scenarios.

- Define CAPEX requirements (ROM) to link to the Budget process

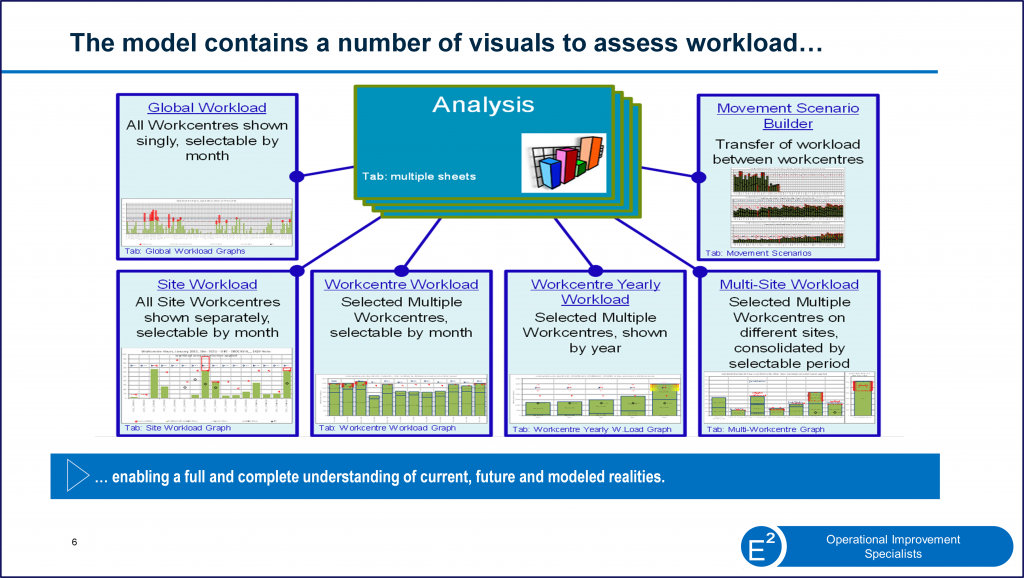

- Produce Site Heat Map

- Site data collection & initial improvement ladders by work center

- Recommend direction and route to execute Operational Scenarios

- Develop detail improvement ladders supported by CAPEX and Operational improvements with Site Teams

- Finalize Asset Strategy Demand-Supply Model

- Validate Asset Strategy / Footprint

- Produce Demand-Supply Model documentation Site Master Plan created for each Site

- Create operational improvement project charters

- Create CAPEX improvement plan including HSE

- Create Production System Deployment Plan

Results

- Custom Full Capacity and improvement modeling capability created to allow rapid running of sales and capacity changes across the network.

- Operational improvement plan for every site in the network was created. Full alignment with BU strategy and goals.

- CAPEX plan dovetailed with operational improvement plan (no double counting or holes)

- Production system deployment plan created.

- The process to run mini strategy updates or full annual updates defined.

- Network consolidation plan.